Winner of the Joan B. Calambokidis Innovation in Masonry Design Award (Young Architect/Engineer Category)

with Shelby Doyle, Erin Hunt and Nick Senske

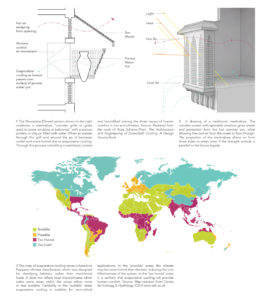

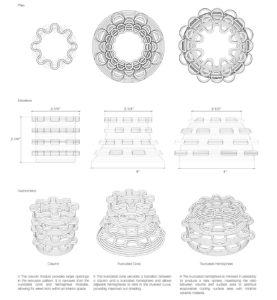

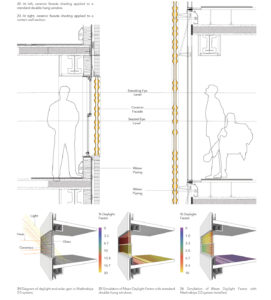

Mashrabiya 2.0 is an evaporative façade design that updates vernacular architecture traditions with 3D printed ceramic assemblies. Mashrabiya are common Arabic lace screens, crafted from an array of small wooden parts, which control light, airflow and privacy. Mashrabiya 2.0 adapts these functions while addressing the performative limitations and materiality of traditional mashrabiya. Instead of a wooden screen, this project proposes a series of ceramic modules to provide evaporative cooling. Three modules: column, truncated cone, and hemisphere, are designed with a woven pattern that produces micro-pores on each piece, allowing for the passage of air through the screen. A Grasshopper script applies data from environmental simulations (DIVA) to generate an optimal sun-shading configuration of modules for a particular architectural application. Once a configuration is determined, the specified ceramic pieces are printed and bonded to 3D printed flexible gaskets. These sub-units are then stacked on a punctured piping system that is designed to spray water vapor onto the bisque fired unglazed ceramics, actively cooling the spaces as air passes through.

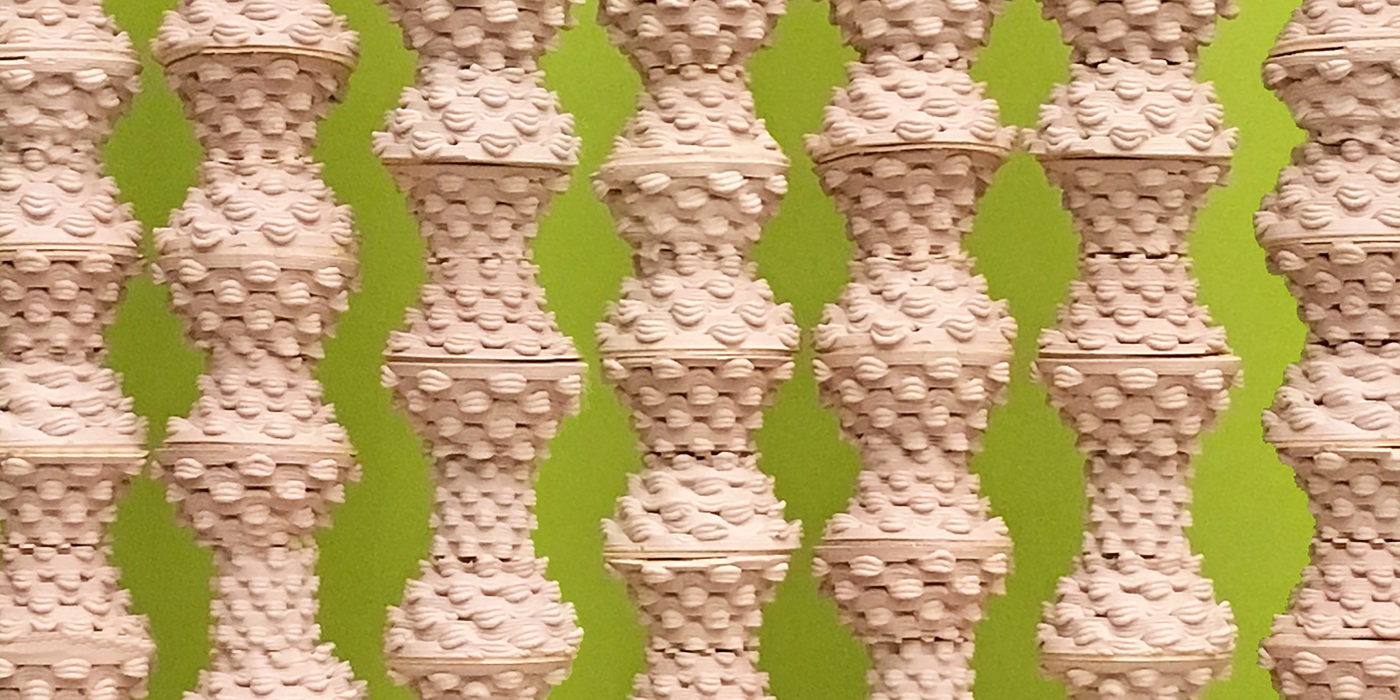

To understand the performance of the system, we constructed a full-scale mock-up of Mashrabiya 2.0. Our prototype represents a residential window measuring 42”x42” and was assembled from standard silt clay printed on a Potterbot 2.0. It contains 140 ceramic modules, produced over a total printing time of fifteen days. Between each ceramic module is a gasket used to cushion compressive forces and seal the space between modules. This is combined with a PLA center that provides lateral stability and installation alignment with the internal piping. To produce a two-material gasket the designs were printed on a LulzBot TAZ 6 with a LulzBot TAZ FlexyDually Tool Head v2 combining standard white PLA with NinjaFlex, a polyurethane (TPU). The ‘almond’ TPU blends with the bisque fired ceramic and becomes integrated into the final design assembly.

Simulations of the mock-up’s solar performance indicated an average reduction in Mean Daylight Factor of ~17% compared to a standard window screen system. This data indicates that Mashrabiya 2.0 may have potential as a building system, particularly in dry and arid climates. Potential applications include retrofits to existing buildings as well as new construction in areas where evaporative cooling is possible, such as the western United States, southern Europe, North Africa, and the Middle East.

While contemporary architects such as Jean Nouvel have experimented with the formal and shading characteristics of mashrabiya, the material properties of clay and the flexibility of 3D printing present an opportunity for further advancements. Emerging Object’s ‘Cool Brick’ provides a precedent an evaporative cooling mechanism.

The design builds upon the ‘Cool Brick’ research and provides several design alternatives. First, Mashrabiya 2.0 is designed as a screen (rather than as a structural unit) for application is new construction or as a retrofit. Second, rather than relying upon grout the project integrates flexible 3D printing between ceramic units. Third, the proposal is integrated into the building mechanical system rather than relying upon rainfall, as arid regions lack adequate rainfall for evaporative cooling. Fourth, the assembled pattern and micro-apertures provide design variation, views, and diversity of shadow and light conditions.

Thus, through ceramic 3D printing, Mashrabiya 2.0 improves upon a traditional architectural form and demonstrates a low-cost, high-performance alternative to contemporary façade systems.