With Shelby Doyle

Parting the Curtain examines the possibilities of 3D printing a house where multiple materials and functions are embedded into a single surface which serves as both enclosure and structure. The aim is to demonstrate that 3D printing is not only a representational medium but also a construction medium. This application allows for furniture, counters, and bookcases to be printed as an extension of the structural spine of the project. Fixtures (toilet, sinks, etc), windows, and doors are off-the-shelf and once selected the form can be calibrated to the unique dimensions and specifications. This design presents a method for democratizing customized living, typically a luxury and pleasure of the wealthy. 3D printing transitions from a generic material practice into one which has functional and programmatic potential driven by personal expression.

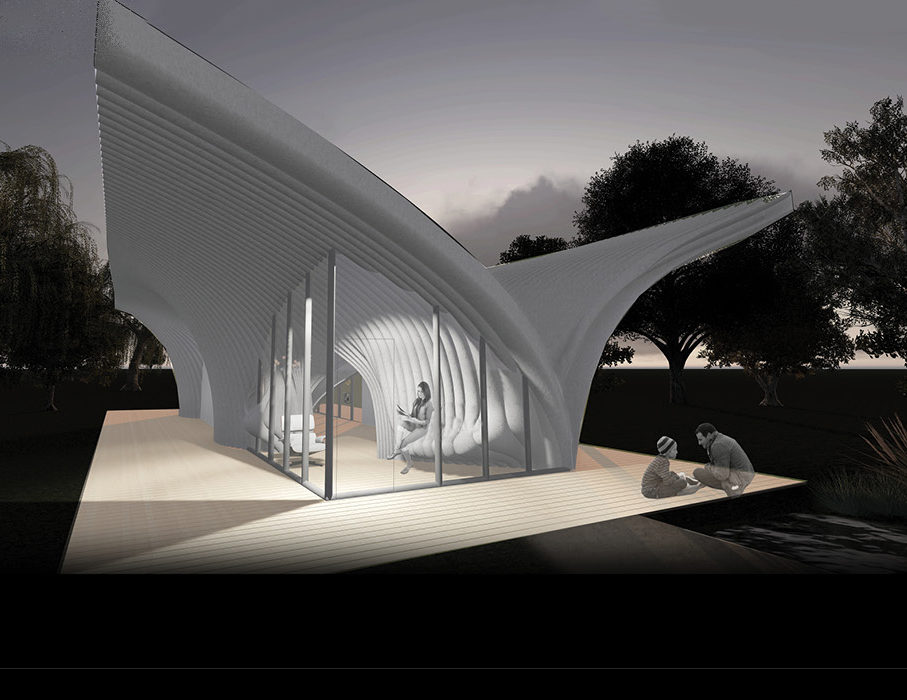

The form of the project began with a 800 square foot shotgun house. The essential elements of the shotgun are: pitched roof to shed water, continuous floor plan for efficient circulation, and porches for shading and solar control. The shotgun form emerged out of the necessity for cheap housing in the rural south and its simple peaked roof is embedded in our collective image of ‘a house’. Here the shotgun roof is inverted and structural efficiency created through a serpentine structural spine that draws upon Thomas Jefferson’s serpentine brick walls at the University of Virginia which demonstrate that a single thickness of material can be made strong through geometric balance and calibration. This seemingly low-tech precedents provide a paramedic foundation for the project. The sine curve produces a thin yet dimensionally stable profile.

The profile becomes the functional spine of the house. An aesthetic form not previously available to us is now can be manipulated and fabricated throw digital modeling and 3D printing.

The roof was inverted so that at scale of the site the roof of the house captures and returns rainwater to the site. A series of trees shade the expansive porches created by the inverted roof structure. The thickness of the roof provides insulation from the Tennessee sun and the porches provide a layer of passive cooling and an opportunity for passive ventilation that can be calibrated with the selection of operable windows.

The robotic arm allows for the full scale constructional of vaulting and similar structural methods which would have previously depended upon support material at a representation scale and at full scale would have depended upon formwork or the use of one material system to produce another material system. The combination of carbon fiber and robotic mobility provides a more direct construction of material from the digital model

This high technology allows us to counteract the placelessness of globalization through customization of architectural space.